Casing types

CASING TYPES

Unit casing provides thermal and sound insulation, as well as durability and protection from external influence.

AirVENTS series are available in several types of casing, general properties of which are:

- High Mechanical strength. Class D1 according to EN 1886.

- Corrosion Resistance. Class C4 according to ISO 12944.

- Thermal insulation. Class T3 according to EN 1886.

- Protection from thermal bridges. Class TB3 according to EN 1886.

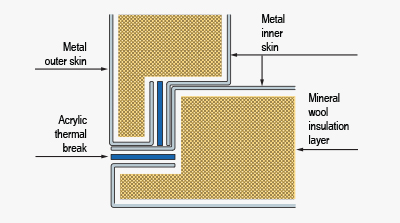

Increased fire resistance, high quality insulation materials. Mineral wool basalt fiber insulation with 90 kg/m3 density. Unlike other types of insulating materials, this material is completely non-flammable and environmentally friendly.

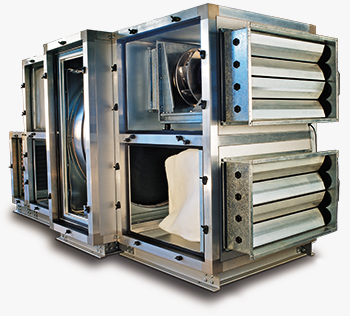

Classic frame design - high strength

The classic casing design is based on aluminum profile frame, joined with corners made of cast aluminum or reinforsed nylon, provides high durability of the unit. Different frame thickness should be used considering the table below:

|

Frame Type |

Recommended area of performance |

Aluminum profile thickness | Thermal insulation thickness | |||

|---|---|---|---|---|---|---|

| 30-25 | up to 20000 m3/h | 30 mm | 25 mm | |||

| 50-50 | 20000-45000 m3/h | 50 mm | 50 mm | |||

| 70-50 | more than 45000 m3/h | 70 mm | 50 mm |

Casing panels are made of steel sheets with a layer of thermal and acoustic insulation from mineral wool. The thickness of the insulation depends on the type of frame (25 or 50 mm).

Casing panel material varies depending on unit application:

Classic unit design with 50 mm zink-aluminum panels in 50 mm frame with cast aluminum corners

Outer panel surface material:

- Zinc-aluminium coating (standard)

- Galvanized steel with polymeric coating (high corrosion resistance)

- Galvanized steel (for internal execution units)

Inner panel surface material:

- Zinc-aluminium coating (standard)

- Stainless steel (for units in hygienic design)

- Galvanized steel

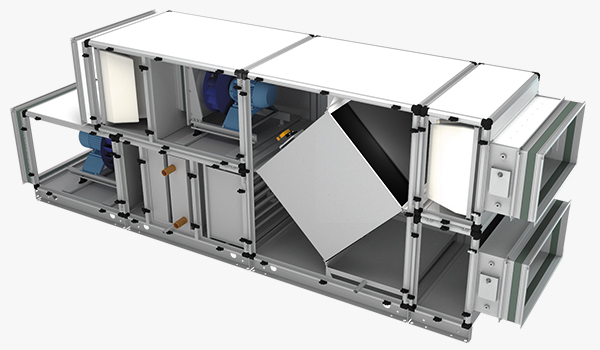

Frameless units - high termal isolation

Frameless design casing system excludes thermal brigdes, usuall for aluminum or steel frame. This significantly increases thermal resistance and reduces heat loss, especially for outdoor installation. It also prevents condensation on the surface when air cooling is on.

Casing panels made of sheet steel with a layer of 40 mm thermal and acoustic insulation from mineral wool. Casing material varies depending on unit application:

Outer panel surface material:

- Zinc-aluminium coating (standard)

- Galvanized steel with polymeric coating (high corrosion resistance)

- Galvanized steel (for internal execution units)

Inner panel surface material:

- Zinc aluminium (Stan

- Stainless steel (for hygienic units)

- Galvanized steel

Benefits of frameless casing:

- better thermal resistance;

- lower weight of the unit;

- no thermal bridges;

- suitable for outdoor installation;

- lower cost;

- higher mechanical strength (compared to 30mm aluminum profile frame).

Frameless unite close up

Frameless casing connection

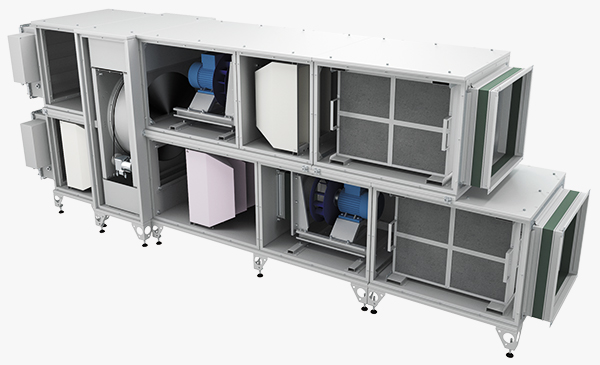

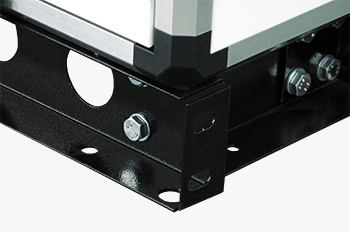

Base frame types

For both classic and frameless unit casing there are several types of base frame avaliable.

| Type | Application (approximately): | |

|---|---|---|

| Adjustable legs made of 2 mm thick galvanized steel | Single-deck units with air capacity up to 20000 m3/h, or double-deck units – up to 15000 m3/h | |

|

Solid base frame made of 2 mm thick galvanized steel | Single-deck units with air capacity up to 35000 m3/h, or double-deck units – up to 25000 m3/h | |

| Solid base frame made of 3 mm thick painted galvanized steel | For unit performance up to 50000 m3/h | |

| Solid base frame made of 4 mmthick painted galvanized steel | For unit performance up to 128000 m3/h |

|

|

|

Solid base frame |

Adjustable legs |

Thank your for your time and your wish to improve our site.