MICRA 80 A3 single room air handing unit with heat recovery

Micra 80 A3 is a heat recovery single-room ventilation unit for balanced energy saving single room ventilation of flats, cottages, social and commercial premises. The unit design required no ductwork layout. The unit offer a simple and efficient ventilation in premises to be refurbished.

Micra 80 A3 is a heat recovery single-room ventilation unit for balanced energy saving single room ventilation of flats, cottages, social and commercial premises. The unit design required no ductwork layout. The unit offer a simple and efficient ventilation in premises to be refurbished.

Features

- Efficient heat recovery ventilation for individual rooms (premises).

- Plate cross-flow heat exchanger made of polymerized cellulose with heat recovery efficiency from 68% up to 77%.

- Centrifugal fans with forward curved blades.

- Asynchronous motors with ball bearings.

- Integrated control system with three operation modes and air flow range from 40 up to 80 m3/h.

- Silent operation (24/32/41 dB(A)).

- Air filtration with two G4 built-in filters.

- Easy mounting.

- Non-stop operation.

Casing

The casing is made of polymer coated metal and is heat- and soundinsulated with 15 mm polyethylene foam layer. The quick detachable from panel provides easy service access to the unit for filter cleaning and removal. Supply of fresh air and removal of extract air are performed through the two 125 mm air ducts.

Air filtration

Two G4 built-in filters provide supply and extract air cleaning. The filters ensure delivery of fresh air free of dust and insects and protect the unit components from contamination.

Air supply and exhaust

The centrifugal fans with forward curved blades provide air supply and extraction. The fan motors with ball bearings are rated for a long service life.

Operating logic

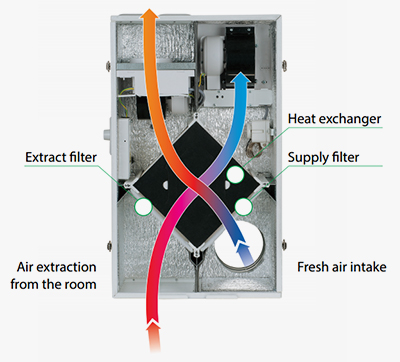

Fresh intake air from outside moves through the filter and the heat exchanger and is delivered to the premise with the supply fan. Warm stale air moves from the room through the filter and the heat exchanger and then is exhausted outside with the extract fan.

Heat energy of warm stale extract air is transferred to cold intake air flow in the heat exchanger. Heat recovery minimises heat losses and heating costs in cold seasons. The intake and extract air flows are fully separated within the heat exchangers and pollutants, odours and microbes contained in extract air are not transmitted to supply air.

Heat exchanger

The unit is equipped with a high-tech plate cross-flow heat exchanger made of polymerized cellulose. The heat exchanger is used to recover extract air heat energy to warm up supply air flow. The heat recovery efficiency reaches 77%.

The applied heat exchanger enables not only heat but also humidity recovery. In warm seasons the heat exchanger operates to cool down supply air and extract excessive humidity. In cold seasons the heat exchanger operates to warm up supply air and humidify it. Due to heat recovery process the unit generates no condensate and requires no condensate drainage.

Freezing protection

The unit is fitted with an integrated freeze protection system. The heat exchanger may be subjected to a freezing danger at low outside air temperatures. The exhaust air temperature falls down as ice accumulates in the heat exchanger.

When exhaust air temperature falls down below a set point the freeze protection thermostat is activated and shuts down the supply fan. The warm extract air flows through the heat exchanger until the extract air temperature rises above the set point. Then the supply fan turns on and the unit reverts to the standard operation mode.

Control and operation modes

The unit is operated with a three-position speed switch.

The control system enables three operation modes:

- Supply and extract ventilation with minimum air flow rate 40 m3/h and minimum noise level 24 dB(A).

- Supply and extract ventilation with medium air flow rate 60 m3/h and minimum noise level 32 dB(A).

- Supply and extract ventilation with maximum air flow rate 80 m3/h and minimum noise level 41 dB(A).

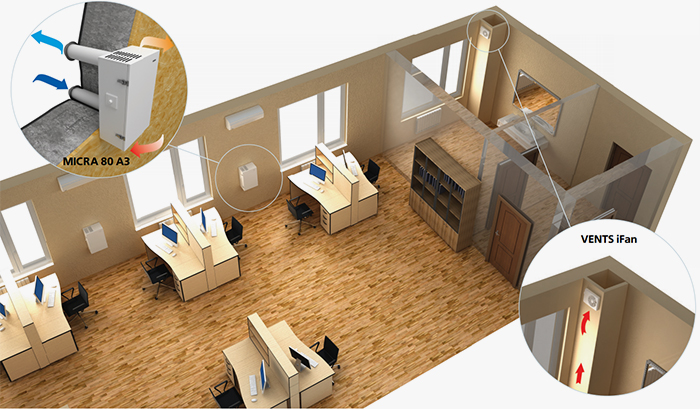

MICRA 80 A3 ventilation system arrangement example

Install one MICRA 80 A3 unit in each room to be ventilated. A single unit is capable to provide efficient ventilation of a premise with the area up to 32 m3/h. A ventilation system based on MICRA 80 A3 is able to provide continuous air exchange and save heat in winter and cool in summer.

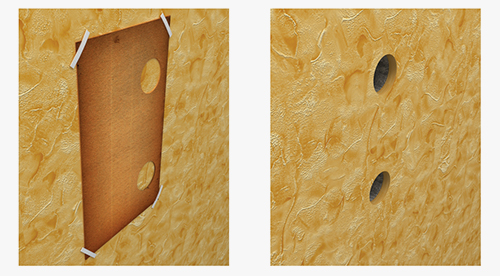

Mark the holes for the air ducts on the wall with the supplied cardboard master plate.

Drill the core holes in the wall and fix the master plate to the wall using a duct tape.

Insert the 125 mm plastic air ducts in the core holes.

The master plate is used to place the air ducts in a required position and align the unit spigots with the air ducts.

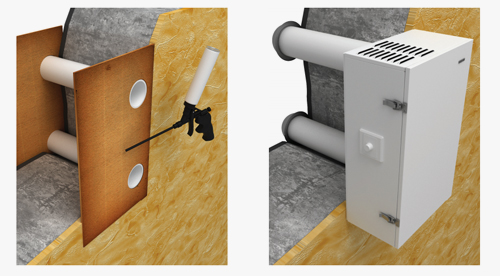

Install the outdoor ventilation hoods from outside to prevent ingress of water and foreign objects inside the unit.

Install the air ducts slightly sloped down to outside to ensure condensate drainage from the unit.

After the air ducts are fixed in required position using the outer ventilation hoods and the master plate fill the gaps between the air ducts and the wall with a mounting foam through the special slots in the master plate.

After solidification of the mounting foam remove the foam excess and cut protruding parts of the air ducts to be flush with wall surface.

To mount the unit casing open the service panel and take off the heat exchanger. Connect the unit spigots to the air ducts and fix the unit casing to the wall with screws and dowels.

After completion of the casing mounting and wiring operations re-install the heat exchanger and the front panel.

Accessories

|

|

|

Stainless steel outer hood |

Round 125 mm telescopic air duct, |

Thank your for your time and your wish to improve our site.