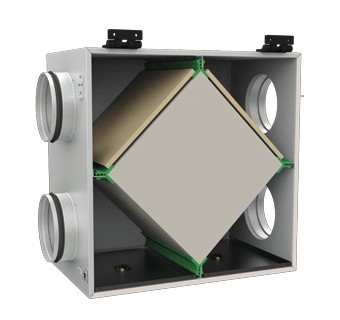

PR series for round ducts

The plate heat exchanger PR 150 unit is an energy saving device designed to save thermal energy by means of thermal energy recovery and is used as a component part of energy saving technologies in buildings and premises.

| Series | Flange diameter [mm] | Type heat exchanger | Filtration class | |||

|---|---|---|---|---|---|---|

|

PR | 150 |

_ - aluminum P - polysterene | G4 |

Application

The plate heat exchanger PR 150 unit is an energy saving device designed to save thermal energy by means of thermal energy recovery and is used as a component part of energy saving technologies in buildings and premises. The unit with a passive heat exchanger is an integral element of ventilation systems of modern buildings and premises. The heat exchanger utilizes extract air thermal energy to warm up filtered supply air which allows reducing thermal energy loss and minimizing heating costs in cold season. The passive heat exchanger is designed for joint operation together with supply and exhaust fans, e.g. VENTS VK 150 fan models.

Design

The plate heat exchanger consists of:

- AlZn casing internally filled with thermal- and sound insulating 15 mm penophole layer;

- plate cross-flow heat exchanger made of aluminium or polystyrene;

- replaceable G4 supply and extract filters.

Features

- Thermal- and sound-insulated corrosion-resistant casing.

- High-efficient counter-flow heat exchanger made of polystyrene or aluminium.

- Recuperation efficiency up to 75%.

- Built-in G4 filters for purification of supply and exhaust air flows.

- Compact sizes and low weight.

Technical parameters

Heat recovery efficiency and air resistance in the air duct are the basic factors that determine the heat exchanger performance.

Coefficient of thermal efficiency is calculated as follows:

![]() ,

,

ts- supply air temperature after heat recuperation;

ti - intake air temperature before heat recuperation;

te -extract air temperature before heat recuperation.

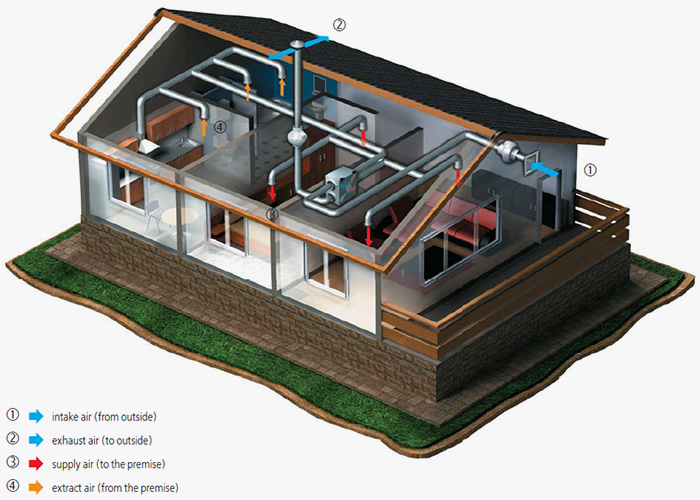

Mounting example

Plate heat exchanger operation example with VENTS VK fans in ventilation system

Plate heat exchanger application example in cottage

Thank your for your time and your wish to improve our site.