NK...U series (rectangular)

Duct electric heater with a control unit.

| Series | Flange dimensions (WxH) [mm] | Heater power [kW] | Phase | Options | ||||

|---|---|---|---|---|---|---|---|---|

| NK | 400х200; 500х250; 500х300; 600х300; 600х350; 700х400; 800х500; 900х500; 1000х500 | 4,5; 6; 7,5; 9; 10,5; 12; 18; 21; 24; 27; 36; 45; 54 | 3 - three phase | U - integrated temperature control |

Applications

Duct electric heaters are designed for heating of intake air in rectangular ventilating system. The heaters are applied for air heating in ventilation and air conditioning systems in various premises.

Design

The casing and the terminal box are made of galvanized steel plate and the heating elements are of stainless steel. The models with the size from 400x200 to 600x350 the electric heating elements are extra ribbed to increase heat exchange surface. NK duct heaters are equipped with two overheating protection thermostats:

- basic protection with automatic restart (operating temperature +50 °С). After cooling the thermostat closes the control circuit of the heater automatically.

- emergency protection with manual restart (operating temperature above +90 °С). In case of response the power supply to the heater is allowed after the manual emergency reset only.

- the thermostat contacts are located in the terminal box for external connection.

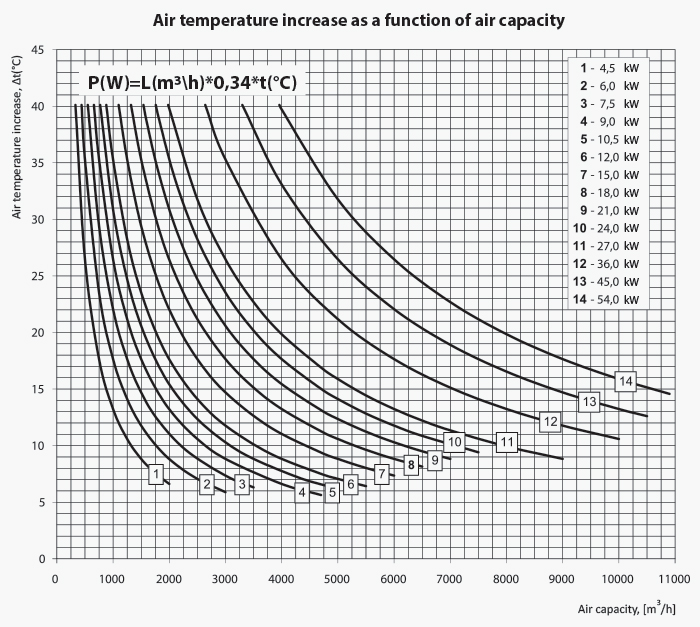

Each standard size has several electric power capacity options. Higher capacity can be attained by means of installation of the heaters in series. In the heaters with heating capacity above 27 kW the tubular heating elements are grouped per 9 kW each. Each group consists of three Δ connected tubular elements.

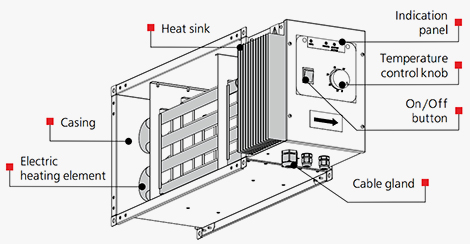

Duct electric heater with NK...U integrated temperature controller

The NK heaters are available in modifications with a control unit for the heaters with power demand from 4.5 up to 54.0 kW to maintain set air temperature in the air duct.

The NK…U model with a control unit is equipped with a three phase triac power control unit.

Power control is effected by means of switching on/off the maximum load commutated by the semiconductor device that is free of any mechanical wear parts. The load commutation starts at zero current and load to disable any magnetic field interferences. The load commutation starts at zero current and load to disable any magnetic field interferences.

The NK…U heaters include two overheat protection thermostats:

- the basic self-resetting overheat protection thermostat actuated at the temperature +50 °C. After cooling the thermostat closes the heater cont rol circuit.

- the emergency overheat protection thermostat with manual reset actuated at the temperature +90 °C. In case of the thermostat tripping power supply is resumed after manual alarm reset.

Operation logic options for the NK…U heater with a control unit:

- operation logic based on temperature sensor readings to maintain set air temperature in the air duct.

- proportional electric heat control from 0 up to 100% with a 0-10 V control signal from the external controller.

The temperature is set with the integrated potentiometer. Optionally, an external 0-10 V control signal from another control unit may be connected to the control unit, which corresponds to the temperature 0 up to +40 °C.

Offered temperature sensor options for the NK...U heater operation logic based on temperature sensor readings (not included into delivery set):

- KDT2-M1 duct temperature sensor enclosed in a protecting sleeve with a sensing tip, 100 up to 400 mm long

- KDT2-M duct temperature sensor enclosed in a protecting sleeve with a mounting flange, 100 up to 400 mm long

- KDT2-MK duct temperature sensor enclosed in a protecting sleeve with a mounting flange, 100 up to 400 mm long

Mounting

The heater design ensures its mounting by means of flange connection. The air flow direction shall match the pointer on the filter. The duct heaters can be installed in any position except for with the electric control unit below to prevent condensate penetration and wiring short circuit.

The mounting shall be performed in such a way as to enable the uniform air stream distribution along the entire cross section.

The air filter shall be installed at the heater inlet to protect the heating elements against pollution.

We recommend to keep such distance between the heater and other system elements which is no less than the heater diagonal, i.e. the distance from one angle to another in its air passage part.

The duct heaters are designed for the minimum air flow 1.5 m/s and the operating air temperature 40 °C. In case of speed control option ensure the minimum air flow through the heater.

Power supply to the heater shall be disabled if the fan is not running.

To ensure the correct and safe heater operation the automation system can be applied to ensure the complex control and protection:

- automatic control of heating elements capacity and air heating temperature;

- checking filter condition by means of differential pressure sensor;

- power supply disabling in case of the supply fan shutdown or airflow speed decrease as well as in case of the built-in overheating thermostats operation;

- shutoff of ventilating system with blowing of electrical heating elements.

Thank your for your time and your wish to improve our site.