NKV series (rectangular)

Duct water heaters are designed for heating of supply air in rectangular ventilating system.

| Series | Flange designation (WxH) [mm] | Number of water coil rows | ||

|---|---|---|---|---|

|

NKV | 400х200; 500х250; 500х300; 600х300; 600х350; 700х400; 800х500; 900х500; 1000х500 | 2; 3; 4 |

Applications

Duct water heaters are designed for heating of supply air in rectangular ventilating system and are applicable in supply or supply and exhaust units.

Design

The heater casing is made of galvanized steel, the manifold is made of copper tubes and the heat exchange surface is made of aluminium plates. The heaters are available in 2, 3 or 4 rows modifications and designed for operation at maximum operating pressure 1,6 MPa (16 bar) and maximum operating temperature +100°С. The exhaust manifold of the heater has a branch pipe for submersible temperature sensor or iicng protecting device. The heater has a nipple to provide the system deaeration.

Mounting

The heater design ensures its mounting by means of a flange connection. The water heater can be installed in any position to enable its deaeration. The air stream shall match the pointer on the heater.

The heater shall be installed in such a way as to enable the uniform air distribution along the entire cross section.

The air filter shall be installed at the heater inlet to provide protection against dust and dirt.

The heater can be installed both at the fan inlet or outlet. If the heater is located at the fan outlet the air duct length between the heater and the fan shall be at least 1-1.5 m to ensure the air flow stabilization as well as permissible air temperature level inside the fan.

The heater shall be connected on the counterflow principle, otherwise its efficiency can drop by 5-15%. All the nomographic charts in the catalogue are valid for such connection.

If waters serves as a heat transfer agent the heaters are designed for indoor installation only. For outdoor installation use antifreeze mixture (i.e. ethylene glycol solution).

To ensure the correct and safe heater operation use the automation system that provides the complex control and freezing protection:

- automatic control of heating elements capacity and air heating temperature;

- switching ventilating system on with preliminary heating by the heater;

- use of air curtains equipped with spring-loaded actuator;

- filter checking by means of differential pressure sensor;

- fan shutdown in case of water coils freezing danger.

|

|

| Connection against air flow | Connection along air flow |

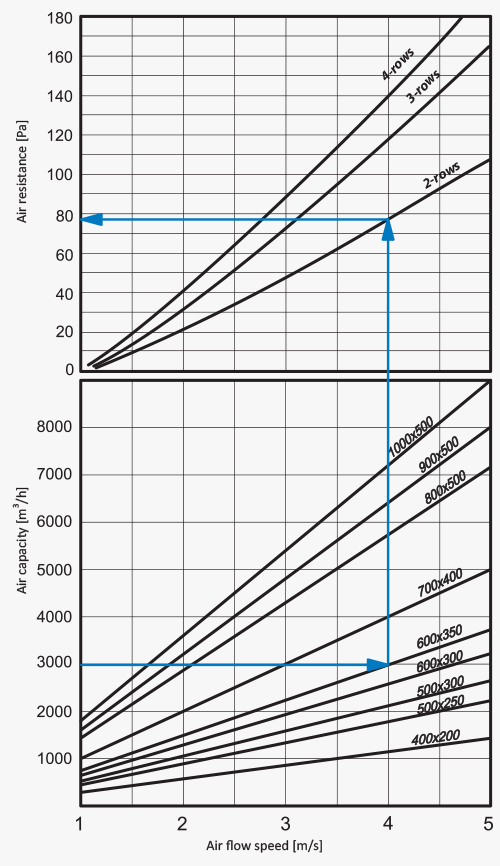

Air pressure loss in the water heaters NKV

NKV rectangular series

Thank your for your time and your wish to improve our site.