OKW series

Duct water coil air coolers are designed for cooling of supply air in rectangular ventilation systems and can be applied in supply or supply and exhaust ventilation systems.

| Series | Flange designation (WxH) [mm] | Number of cooling coils | ||

|---|---|---|---|---|

|

OKW | 400х200; 500х250; 500х300; 600х300; 600х350; 700х400; 800х500; 900х500; 1000х500 | 3 |

Applications

Duct water coil air coolers are designed for cooling of supply air in rectangular ventilation systems and can be applied in supply or supply and exhaust ventilation systems.

Design

The water coolers are available in OKW and OKW1 mofications. The OKW1 cooler has a simplified design.

The cooler casing is made of galvanized sheet steel, the manifold is made of copper tubes and the heat exchange surface is made of aluminium plates. The cooling coils are available in 3 rows modification and designed for the maximum operating pressure 1.5 MPa (15 bar). It is equipped with a droplet separator and a drain pan for condensate collection and removal.

For OKW and OKW1 models by default the service side is located on the right side from the air stream direction. The OKW cooler service side location can be changed by coil turning by 180°. The OKW1 modification does not have this option.

Mounting

- Mounting is effected by means of flange connection. The water cooling coils can be installed only horizontally to enable the unit deaeration and condensate draining.

- The installation shall be performed in such a way as to enable the uniform air distribution along the entire cross section.

- The air filter shall be installed at the cooler inlet to protect the cooler against dirt and dusting.

- The cooler can be installed both at the fan inlet or outlet. If the cooling coils are located at the fan outlet the air duct between the cooler and the fan shall have the lehgth 1 to 1.5 m to ensure the air flow stabilization.

- To attain the maximum cooling capacity the cooler must be connected on counter-flow basis. All the nomographic charts in the catalogue are valid for such connection.

- If water serves as a cooling agent, the coolers are suitable for indoor installation only in the premises with the indoor temperature not below 0 °C. For outdoor installation use an antifreeze mixture, i.e.ethylene glycol solution.

- The droplet separator is made of polypropylene profile and prevents condensate dripping from the cooling tubes by the cooling air flow. While selecting a cooler type consider that the most suitable speed of the air flow for the efficient droplet separator operation is up to 4 m/s.

- Condensate drain from the cooler shall be performed through the U-trap. The U-trap height depends on the total pressure in the fan and can be calculated using the figures and the table below.

|

|

Н - U-trap height К - drain height Р - total pressure in the fan |

- To ensure the correct and safe cooler operation use the automation system providing the complex control and automatic regulation of the cooling capacity and air cooling temperature.

|

|

|

Counter flow connection |

Parallel flow connection |

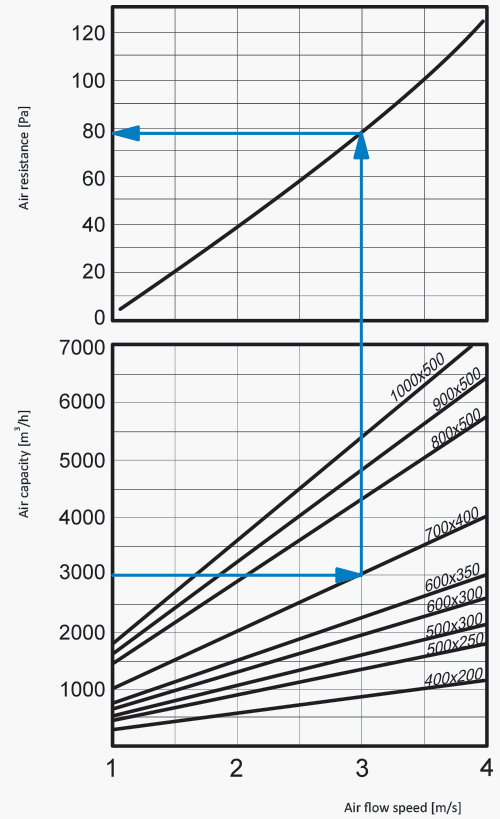

Air pressure loss in water coolers

Rectangular OKW series

Thank your for your time and your wish to improve our site.