| APPLICATION |

- This fan model fits for the following applications:

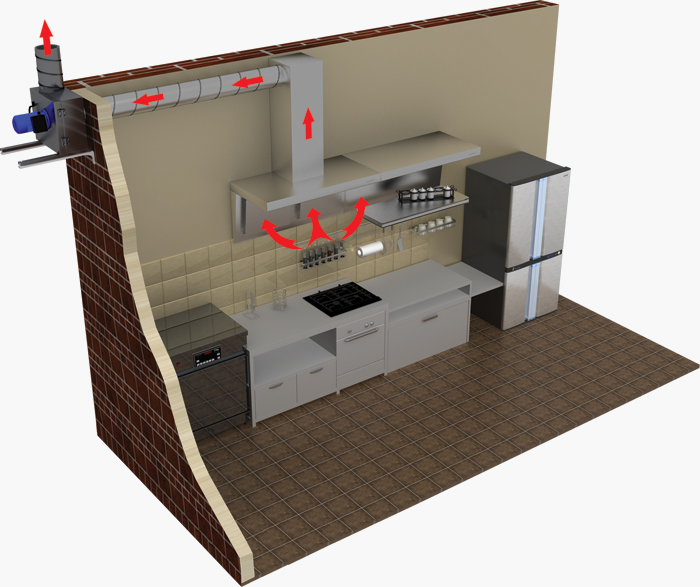

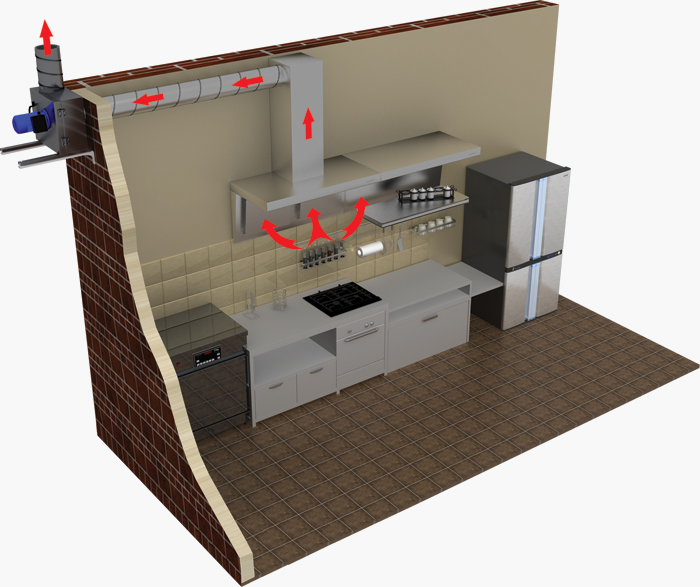

- kitchen exhaust ventilation systems;

- exhaust ventilation systems for removal of post-welding gases;

- industrial bakery ventilation systems.

|

- The fan is designed for ventilation of contaminated, grease-laden, humid and hot air with temperature up to 120 °С in conditions of high air resistance in the system.

|

| DESIGN DESCRIPTION |

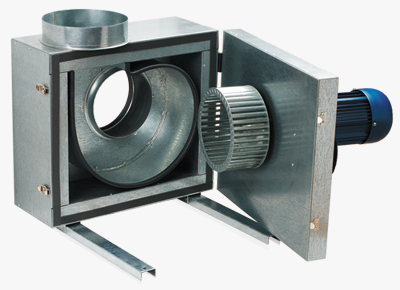

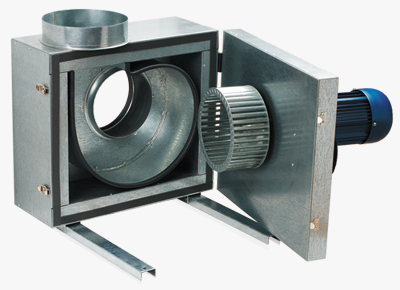

- The fan casing is made of galvanized steel plate and is internally insulated with 50 mm mineral wool layer.

- The swivel block of the impeller and motor provides easy access to the fan internals for easy and effective cleaning.

- The intake and exhaust flange diameter match with standard ventilation air ducts.

- The flanges are equipped with a rubber sealing.

- The fan is installed in the mounting frames with integrated vibration connectors.

|

| ELECTRIC MOTOR |

- Equipped with a highly reliable single-phase or threephase motor with squirrel-cage rotor and steel highperformance centrifugal impeller with forward-curved blades (for sizes 150 to 250 mm) or backward-curved blades (for sizes 315 to 450 mm).

|

- The impeller is mounted on the motor shaft and is balanced statically and dynamically.

- The motor has F class motor winding insulation and IP54 ingress protection rating.

|

| SPEED CONTROL |

- The fan has both step and smooth speed control options with a transformer or frequency speed controller.

|

- Several fans may be connected to one controller if the total power and operating current do not exceed the rated controller parameters.

|

| MOUNTING |

- The fan is designed for connection to round air ducts.

- The fan is fixed to the wall with the mounting bracket KM-KSK (separate delivery).

|

- The fan is connected to power mains on the terminal box on the motor.

- The cable length must be sufficient with respect to the motor-impeller block movement.

|

|

Domestic fans

Domestic fans  Industrial and commercial fans

Industrial and commercial fans  Single-room ventilation systems with heat recovery

Single-room ventilation systems with heat recovery  Air handling units

Air handling units  Air heating systems

Air heating systems  Smoke extraction and ventilation

Smoke extraction and ventilation  Air sterilizers

Air sterilizers  Accessories for ventilating systems

Accessories for ventilating systems  Electrical accessories

Electrical accessories  Ventilation ducts and fittings

Ventilation ducts and fittings  Air distribution components

Air distribution components  Ventilation kits and vents

Ventilation kits and vents