VENTS VUT EVK mini EC air handling units with heat recovery

Air handling unit in heat- and sound-insulated casing with electric heater and kitchen hood. Air capacity up to 270 m3/h, heat recovery efficiency up to 95%.

| Series | Rated air capacity, m3/h | Heater type | Duct connection | Modification | Type | Motor type | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

VENTS VUT |

300 - unit with a built-in control panel; 301 - unit with an external control panel. | E - electric | V - vertical | К - kitchen hood | mini | ЕС - synchronous electronically commutated motor |

Description

The air handling units VUT 300/301 EVK mini EC units with heat recovery connected to the kitchen hood are the ideal solution for energy-saving ventilation of the flats and cottages. The units have two operation logics:

- Heat recovery operation mode. When the kitchen hood is turned off, air is extracted through the air ductworks and transfers heat to supply air through the heat exchanger.

- Kitchen hood operation mode. When the kitchen hood is turned on, air is extracted through the kitchen hood and is exhausted directly through the exhaust duct outside. Both operation modes provide balanced ventilation in the room.

Compatible with round Ø125 mm air ducts.

Modifications

VUT 300 EVK mini EC - unit with an integrated control panel;

VUT 301 EVK mini EC - unit with an external control panel.

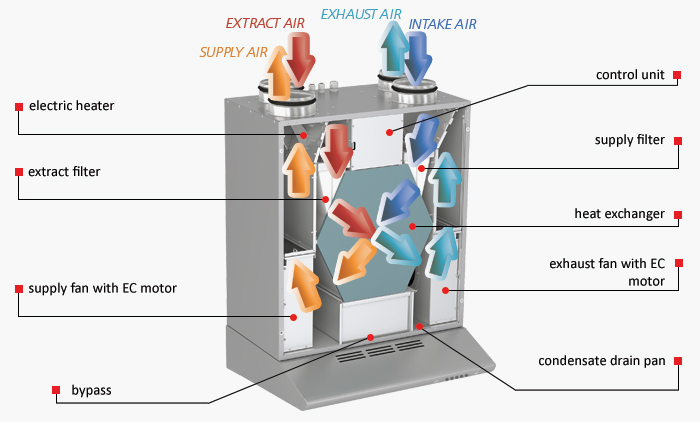

Unit design

Casing

Made of white high-quality polymer coated steel, internally filled with 15 mm cellular polypropylene heat- and sound-insulating layer.

Filter

Supply and extract air flows are purified through two bag filters with filtering class G4. The kitchen hood is equipped with a multi-layer aluminium fat filter. The replaceable filter with filtering class F7 is optionally available.

Fans

High-efficient electronically-commutated motors with external motor and impeller with backward curved blades.

Such motors are the most state-of-the-art energy-saving solution.

EC motors are featured with high performance and total speed controllable range. High efficiency reaching 90% is the premium advantage of the electronically-commutated motors.

Heat exchanger

Counter-flow polystyrene heat exchangers with high heat recovery efficiency. The drain pan under the heat exchanger block ensures condensate removal.

In case of freezing danger determined by the temperature sensor the supply fan is turned off for the period required for the heat exchanger defrosting. The heat exchanger is easily removed for cleaning. When the kitchen hood is turned on, extract air is directed from it directly to the air duct, passing by the heat exchanger.

Heater

The unit is equipped with an electric heater located downstream of the heat exchanger to warm up supply air um to set comfortable temperature up to +30 °C. The heating electric elements have active overheating protection controlled by the temperature sensor in the air duct and two overheating thermostats. The first one is actuated at +50 °C and has automatic reset and the second one is actuated at +90 °C and has manual reset. Air supply to the electric heating elements at the end of the heating cycle ensures cooling of the electric heating elements.

Control and automation

The unit has integrated automation with the control from the multifunctional built-in control panel for the VUT 300 EVK mini EC model or the external control panel for the VUT 301 EVK mini EC model. Both models are controllable from a remote controller (optional accessory). The speed control buttons for the kitchen hood mode are located on the front panel of the kitchen hood.

Control and protection functions:

- Turning the unit on/off from the control panel. Air supply to the electric heating elements during the unit shutdown.

- Three fans speeds are adjusted during the system setup.

- The heat exchanger downstream of the heat exchanger warms up supply air flow up to the comfortable temperature.

- Input for alarm signal from the fire fighting system.

- The supply fan is turned off in case of freezing danger for the period required for the heat exchanger defrosting.

- Changeover between heat recovery and kitchen hood operation modes.

- Relay input for connection of the CO2 / humidity / IAQ or any other sensor that switches the unit to maximum speed.

- Filter clogging control by motor hours.

- Unit week schedule setting.

Controllable ventilation on demand:

The unit is equipped with a contact for relay signal from an external sensor. The unit operation according to an external sensor (for example, CO2 sensor) enables to reduce energy demand.

Operation logic of the unit with CO2 sensor: An unoccupied ventilated premise has low CO2 concentration and requires no intensive ventilation. The unit operates at low speed for minimum permanent ventilation.

As people come inside, CO2 concentration in the premise increases and the signal from CO2 sensor closes relay contact.

The unit is turned to maximum speed until CO2 concentration in the room drops down and the contact is opened. After that the unit reverts to the minimum speed.

To arrange this operating logic it is required to connect any sensor with relay output and to connect it to the respective unit input. The sensor is available upon separate order.

Mounting

The unit must be fixed to the wall with anchor bolts in a position that enables condensate drainage. While mounting the unit provide service access on the front panel side.

To ensure the correct supply air warming up function, install the duct temperature sensor in the supply air duct (included in the delivery set) not more than 1 m from the supply air duct end.

Extra accessories

CO2-1 or CO2-2 sensors are recommended for arrangement of automatic control of air capacity and extra energy saving.

Application example

Thank your for your time and your wish to improve our site.