VENTS KSA series

Compact sound- and heat-insulated centrifugal fans with forward-curved impeller blades and the air capacity up to 2140 m3/h. Applied in supply and exhaust ventilation systems for premises with high requirements to noise level. Compatible with Ø 100, 125, 150, 160, 200, 250 and 315 mm round ducts.

| Series | Spigot diameter | Polarity | Phase | Options | ||||

|---|---|---|---|---|---|---|---|---|

|

VENTS KSA | 100; 125; 150; 160; 200; 250; 315 | 2, 4 | E - single phase |

R - power cord with IEC C14 electric plug. U - speed controller with electronic thermostat and temperature sensor integrated into the air duct. Equipped with power cord and IEC C14 electric plug. Temperature-based operation logic. Un - speed controller with electronic thermostat and external temperature sensor fixed on 4 m cable. Equipped with power cord and IEC C14 electric plug. Temperature-based operation logic. U1 - speed controller with electronic thermostat and temperature sensor integrated into the air duct. Equipped with power cord and IEC C14 electric plug. Timer-based operation logic. U1n - speed controller with electronic thermostat and external temperature sensor fixed on 4 m cable. Equipped with power cord and IEC C14 electric plug. Timer-based operation logic. |

Applications

KSA fan design enables their application in supply and exhaust ventilation systems for the premises with high noise level requirements. Suitable for connection with Ø 100, 125, 150, 160, 200, 250 and 315 mm round ducts.

Design

The fan casing is made of aluzink. Heat- and sound-insulating layer is made of polystyrene foam.

Motor

The impeller made of galvanized steel and forward curved blades is powered by means of the 2- or 4-pole asynchronous motor with external rotor. The motor is equipped with the ball bearings for long service life. For precise features, safe operation and low noise, each impeller is dynamically balanced while assembly. Motor protection rating IP 44.

Speed control

Smooth or step speed control with a thyristor or autotransformer speed controller. Several fans may be connected to one speed controller provided that the total power and operating current do not exceed the rated speed controller parameters.

Mounting

Connection pipes have round section. The basic version of the fan includes the power cord with no plug. The power cord and С14 (КSА…R) plug are available on separate order

Electric connection and mounting shall be performed in compliance with the operation manual and wiring diagram.

The fan with electronic temperature and control module (U option)

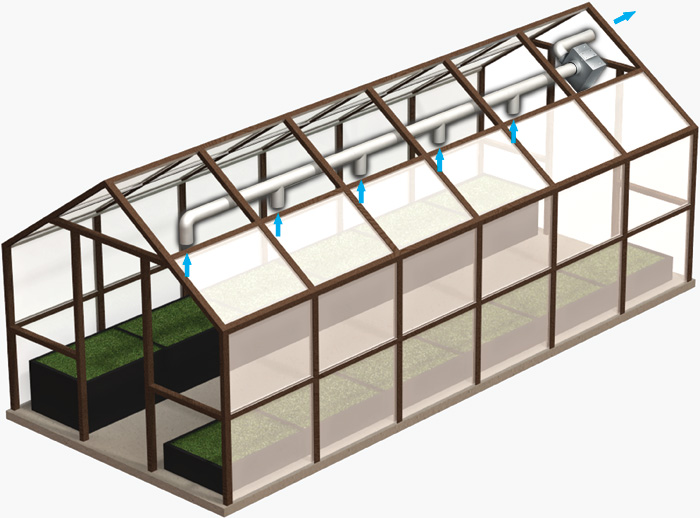

The ideal solution for ventilation of the premises requiring permanent temperature control, i.e. greenhouses. The fan with the electronic temperature and speed control module provides automatic control of the motor speed (air capacity) depending on air temperature in the air duct or in the room.

The fan front panel has the following control knobs:

- speed control knob for setting the motor speed;

- thermostat control knob for setting the temperature set point;

- thermostat indicator light.

The fan is available in two modifications:

- with the temperature sensor integrated inside the fan air duct (U/U1 option);

- with the external temperature sensor fixed on the cable, 4 m long (Un / U1n).

Control logic of the fan with the electronic temperature and speed control module

Set the desired air temperature (thermostat set point) by turning the thermostat control knob. Set the required minimum impeller speed (air flow) by turning the speed control knob. The motor switches to maximum speed (maximum air flow) as the temperature reaches and exceeds the set temperature set point. The motor switches to the preset lower speed as the temperature drops down below the temperature set point. To avoid frequent motor speed switches when the air temperature in the duct is equal to the set temperature point, the speed switch delay is activated. There are two switch delay patterns for various cases:

- The temperature sensor-based switch delay (U option): the motor switches to higher speed as the air temperature exceeds 2 °C above the set thermostat set point. The motor revers to the preset lower speed as the air temperature drops below the thermostat set point. This pattern is used to keep air temperature to within 2 °C. In this case the motor speed switches are rare.

- The timer-based switch delay (U1 option): as the air temperature exceeds the set thermostat set point, the motor switches to higher speed and the switch delay timer is activated for 5 min. The motor reverts to lower speed as the air temperature drops down below the thermostat set point and only after 5 minuts timer countdown. This pattern is used for exact air temperature control. The speed switches for the fan with U1 option are more frequent as compared to the operating logic of the fan with U option, however the minimum operating cycle at one speed is 5 minutes.

VENTS KSA fan greenhouse ventilation example

Thank your for your time and your wish to improve our site.